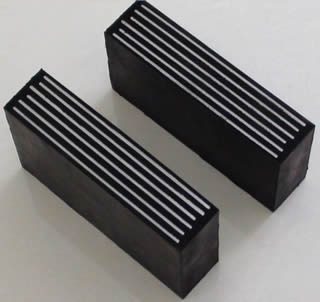

Laminated Elastomeric Bearing Pads

Laminated elastomeric bearing features reinforced steel plates that are sandwiched between layers of rubber through vulcanization and molding manufacturing process to form a homogeneous unit. Not only do these embedded steel plates limit excessive expansions, but also increase transversal, longitudinal and compressive strength as well as rotation capability comparing with plain elastomeric bearings.

Features:

Laminated elastomeric bearing

- Capable to withstand severe vertical loads and external forces.

- High accommodation of movements caused by expansion, contraction, concrete creep effects and shrinkage, etc.

- Allow for rotations of the bearing in any horizontal axis caused by deflections or misalignments.

- Absorb vibrations and isolate sounds.

- Great traction resistance.

- Corrosion free in that the steel plates are embedded in the rubber without contact of air.

- Easy to install.

Applications:

- Bridges with small displacements and short span.

- Load bearings of building structures.

- Flyovers.

Types:

Normally, different shapes of laminated elastomeric bearings suit different types of applications. For example, rectangular bearings are ideal for orthogonal bridges, while round bearings are suitable for oblique crossing and cylindrical pier bridges. Round bearings with spherical surfaces are the best choice for curved bridges with 3% to 5% slopes.

Load distribution & movement accommodation of laminated elastomeric bearing

Details:

- Materials: quality natural rubber, neoprene or others to suit your scheme.

- Thickness: 1/8” to 30” or custom thickness.

- Width: 36” to 48” or custom widths.

- Shapes: rectangular, square or round (with optional holes for anchor bolts as your request).

- Hardness: 50 to 70 durometer complying with AASHTO.

- Standards: AASHTO, ASTM D4014, BS EN 1337 or other standards according to your requirements.