An Economical Choice - Plain Elastomeric Bearings

Plain elastomeric bearings, also known as non-reinforced elastomeric bearings, are exclusively made of natural rubber or neoprene (with better durability). They provide a low-cost choice for bridges with lighter bearing loads.

Features:

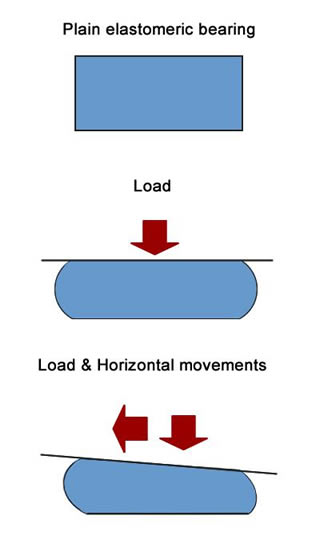

Plain elastomeric bearing

- Quality materials including natural rubber, neoprene complying with AASHTO standards.

- Allow for expansions and contractions of precast steel structure of bridges.

- Capable to control load distribution, meanwhile accommodate thermal and end-beam rotational movements.

- Vibration, sounds and shocks isolation.

- Avoid excessive load eccentricity and edge compression.

- Simple but robust structure.

- Lower price than laminated elastomeric bearing.

- High cost effectiveness.

- Minimal maintenance is needed.

Applications:

Load distribution & movement accommodation of plain elastomeric bearing

- Construction of flyovers.

- Machinery and pumps.

- Short-span bridges.

- Prefabricated structures.

- Leveling pads for girder bridges.

- Support commercial and industrial buildings.

- Petrochemical and power plants.

Details:

- Material: natural rubber, neoprene and others as your request.

- Thickness: 1/8” to 30” or custom thickness.

- Width: 36” to 48” or custom widths.

- Shapes: rectangular, square or round

- Hardness: 50 to 70 durometer complying with AASHTO.

- Standards: AASHTO, ASTM D4014, BS EN 1337or other standards according to your requirements.

- Physical properties:

| Material | Neoprene | Natural rubber | ||||

|---|---|---|---|---|---|---|

| 50 | 60 | 70 | 50 | 60 | 70 | |

| Hardness (Shore A) | 45 to 55 | 55 to 65 | 65 to 75 | 45 to 55 | 55 to 65 | 65 to 75 |

| Tensile strength (min) | 2250 psi | 2250 psi | 2250 psi | 2500 psi | 2500 psi | 2500 psi |

| Elongation (min) | 400% | 350% | 300% | 450% | 400% | 350% |

| Compression set (max) 22 hours | 35% at 212 °F | 35% at 212 °F | 35% at 212 °F | 25% at 158 °F | 25% at 158 °F | 25% at 158 °F |