Study on Construction Method for Buttress and Related Embedded Parts Below Isolation Bearings

This paper adopts different pouring methods to test the buttress under isolation bearings, which including conventional test methods, second pouring methods with fine stone concrete, second pouring methods with highly strong grouting material, pouring methods of pouring first without putting embedded parts and inversion pouring methods, and makes emphatically analysis for the test result, including the concrete plane aperture ratio of embedded buttress and distribution diagram of hole. The testing result is meaningful for the similar project.

Introduction

Seismic isolation technique develops rapidly since Wenchuan earthquake in 2008, especially after Ya’an earthquake in 2013, government pay more attention to the seismic isolation technique and support it. In 2014, the Ministry of Housing and Urban Construction issued “a number of opinions on the use of sheltering technology in housing construction projects”. Thereafter, some seismic isolation buildings spring up like mushrooms in high intensity area. Since new edition “map of seismic parameters in China” is carried out on 1st June,2016, the overall intensity of fortification has improved in Tianjin, and seismic isolation technique is more and more widely used. In recent years, lots of domestic experts have studied on the seismic isolation technique, but some problems appeared in actual construction process, such as the pouring concrete under embedded parts isn’t firm, anchoring bar has clashes with buttress or pulling beam steel, embedded parts installed uneven, bearing’s installation has eccentricity and so on. The uneven pouring of concrete below the embedded parts is a very prominent problem because the height of the bearing is very high and the height of the strut is flat causing no flowing pressure difference between concrete. So what kind of construction methods can be used to effectively solve the problem should be in-depth study. For this purpose, there proposed five construction schemes for comparing the pouring quality of buttress under bearing.

1. Test schemes and component size

1.1 Test scheme

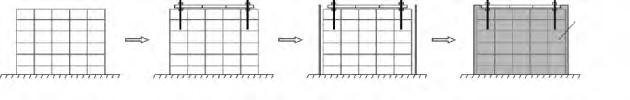

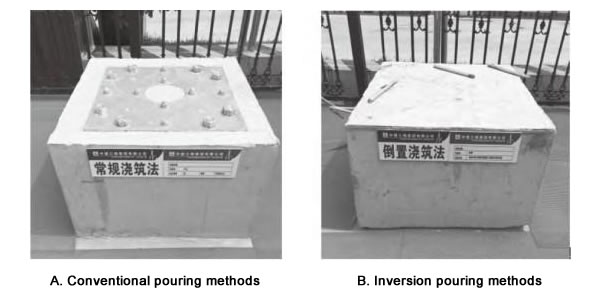

(1)Conventional pouring methods. Firstly, tie the reinforcement to the pier. Then, fix embedded parts, and finally pour concrete. Construction process: tie to the reinforcement of pier→install embedded parts →support shuttering for buttress →pour concrete (completed pouring by one time), as shown in the Figure 1.

Figure 1 Process of conventional pouring methods

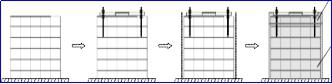

(2) Second pouring methods with fine stone concrete. It means the whole pouring process is completed by two times pouring. The first time is to pour the place under the connection plate below 100m, the second time is to pour the remaining parts with fine stone concrete.

Construction process: tie the reinforcement to the pier→ install embedded parts→ support shuttering for buttress→ pour concrete (second pouring is accomplished). Before the second pouring, plane position, elevation and levelness of the embedded plate should be re-checked, as shown in the Figure 2.

Fine stone concrete

Figure 2 Process of second pouring methods with fine stone concrete

(3)Second pouring methods with highly strong grouting material. It is similar with the second method, the only difference is that the second time pouring is with highly strong grouting material.

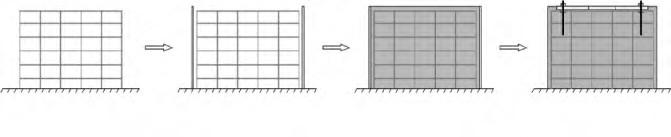

(4)Pouring first before putting embedded parts. It means pouring concrete to the bottom elevation of buttress first, then putting the embedded parts into the buttress.

Construction process: tie the reinforcement to the pier→ support shuttering for buttress→ pour concrete→ install embedded parts. As shown in the Figure 3.

Figure 3 Process of pouring first before putting embedded parts

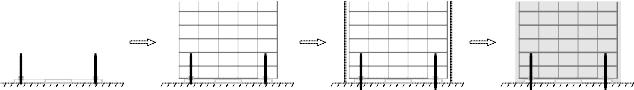

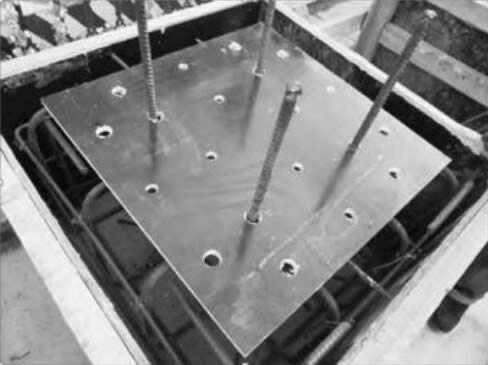

(5)Inversion pouring methods. It means to inverse the embedded parts, steel bar and shuttering, then pour the concrete.

Concrete process: place the embedded parts→ tie the reinforcement to the pier→ support the shuttering→ pour concrete, as shown in the Figure 4.

Figure 4 Process of Inversion pouring methods

Before each pouring test, all concrete slump should be measured, next step should be carried out after meeting regulatory requirements.

In order to inspect the pouring effect of buttress in different size, this scheme is conducting a test with two size buttress (900mm x 900mm and 1200mm x 1200mm), Testing scheme as shown in Table 1.

| Test Type | Test Purpose | Size of embedded parts | |

| Conventional pouring methods | Inspect its construction quality and compare it with other methods | 670mm×670mm 970mm×970mm |

|

| Second time pouring methods | Fine stone concrete | Inspect its construction quality | 670mm×670mm 970mm×970mm |

| Highly strong grouting material | Inspect its construction quality | 670mm×670mm | |

| Pouring first before putting methods | Inspect its construction quality | 670mm×670mm | |

| Inversion methods | Inspect its construction quality | 670mm×670mm | |

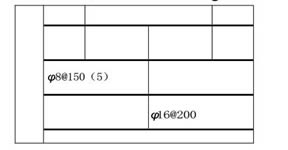

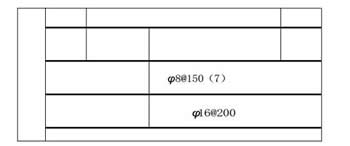

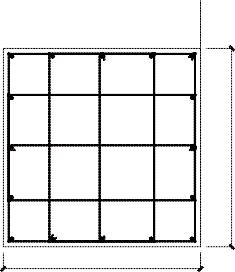

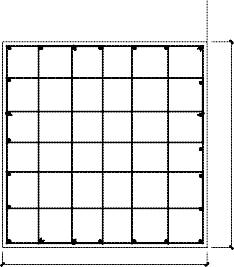

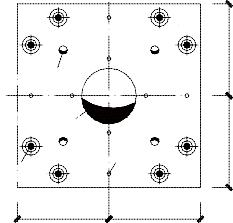

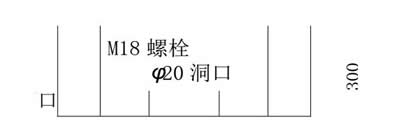

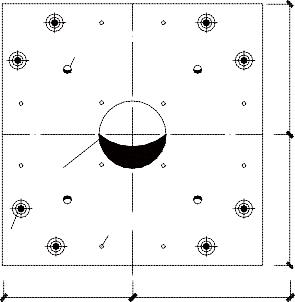

1.2 Component Size

In this test, the isolation bearings under buttress size are 900mm x 900mm x 600mm and 1200mm x 1200mm x 600mm, embedded plate sizes are 670mm x 670mm and 970mm x 970mm, The diameter of 200, 250 mm vent holes are reserved in the middle of the embedded plate, and in the meanwhile, the diameter of 30 mm vent holes are also reserved in the four corners of embedded plate. The anchor rod size of embedded plate is 22mm, bolt size of embedded plate is M18 each, as shown in Figure5-7.

A. Sectional view (a)

B. Sectional view (b)

Figure 5 Sectional view of pier

In order to conveniently compare the effect of different construction methods, this scheme adopts corresponding adjustment for the embedded part, so the scheme cancels sleeve and uses anchor bar & bolt (replace original stud) to go through embedded parts directly connected by nuts up and down the embedded parts, after the test, the embedded parts can be taken out by unfastening nuts.

A. Plan (a)

B.Plan (b)

Figure 6 Plan of pier

A. Embedded plate (a)

B. Embedded plate (b)

Figure 7 Embedded plate

2.Field test

2.1 Technique preparation before test

(1)Tie the reinforcement to the pier, and fix shuttering. One of buttress which used for the pouring first before putting construction needs to be fixed with 4 pieces spacer bar at the bottom of plate, the rebar should go through four small gas vents exactly, as shown in Figure 8.

Figure 8

Figure 9

(2)Fixed embedded parts. One of embedded parts which used for the inversion construction should be put at the bottom of buttress. As shown in Figure 9.

(3)In order that the concrete slurry pours into the bolt hole which leads to the unsuccessfully remove of the late embedded plate when pouring the concrete, the bolt can be covered by some plastic bags. As shown in Figure 10.

Figure 10 Construction site

2.2 Pouring process

Pouring order of seismic isolation buttress is as follows: conventional pouring methods (670mm x 670mm embedded parts), conventional pouring methods (970mm x 970mm embedded parts), pouring first before putting parts methods (670mm x 670mm embedded parts), second time pouring with fine stone concrete methods (670mm x 670mm embedded parts),second time pouring with fine stone concrete methods (970mm x 970mm embedded parts), second time pouring with highly strong grouting material methods (670mm x 670mm embedded parts), inversion pouring methods (670mm x 670mm embedded parts).

Conventional pouring methods (670mm x 670mm embedded parts)

Second time pouring with highly strong grouting material methods

(670mm x 670mm embedded parts)

inversion pouring methods (670mm x 670mm embedded parts).

The pouring process should be in accordance with actual construction process of buttress, grouting should be carried out from the middle grouting hole and surrounding area of embedded parts. And vibrating sticks are used to vibrate it until the concrete slurry fills up the four gas vents. For the buttress by second time pouring methods, the first time concreting should be poured to the 100mm place under embedded parts, the second time should be poured to the top elevation of embedded parts.

3. Test result and conclusion

3.1 Test result

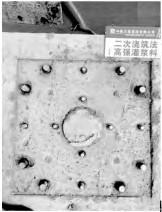

The shuttering should be tore down after finishing pouring the buttress for a week. In process of tearing down, first screw out the nut of the embedded parts, then use crow bar to pry the four corner repeatedly until the embedded can be taken out. As shown in Figure 11.

Taking photos for the buttress surface after tearing down the embedded parts, then demarcate the hole on the photos by CAD software and make calculation for the hole ratio. The distribution of the holes in the partial buttress is shown in Figure 12.

3.2 Conclusion

Collecting the above 7 sets of test data and hole ratio of different construction methods as shown in figure2. As shown from the table: hole ratio is maximum in conventional pouring methods which is mostly used at present, it gets 32.66%. The hole ratio is less)in second time pouring methods. Its hole ratio of second time pouring with highly strong grouting material is 7.76%, which is much less than conventional pouring methods. Buttress size is bigger, hole ratio is less. The hole ratio data of inversion pouring methods is close to 0.00%.

| Test Type | Size of embedded parts | Hole ratio | |

| conventional pouring methods | 670mm×670mm | 32.66% | |

| 970mm×970mm | 26.81% | ||

| Pouring first before putting method | 670mm×670mm | 21.93% | |

|

Second time pouring methods |

Fine stone concrete | 670mm×670mm | 16.46% |

| 970mm×970mm | 14.31% | ||

| Highly strong grouting material | 670mm×670mm | 7.76% | |

| Inversion methods | 670mm×670mm | 0.00% | |

Thus, when concreting the buttress below seismic isolation, it is recommended to adopt the second time pouring with highly strong grouting material, The construction of the inversion methods for future prefabricated production is still to be further studied.